Solenoid and Piston Valves

M&M International UK Ltd can offer a wide range of Solenoid and Piston Valves that can be used in a variety of different applications.

You can view a list of examples with PDF files for:

Piston Valves

M&M Angle seat piston valves

M&M piston valves are manufactured in Italy, using the highest quality materials for a high quality product.

M&M piston actuated valves use an external control media to pilot the actuator, where a piston valve is directly connected to the main seal that closes onto the main orifice, thereby controlling the flow of liquids and gases.

M&M piston valves are highly recommended under these conditions:

Media containing dirt particles

Highly viscous media (up to 600 cST (80°E); 1 centistoke = 1 mm2/s)

High flow volumes

High temperatures

Damp environments or hazardous locations

Technical Information

The main seal material used in piston actuated valves:

A modified PTFE has been used as the main seal material since 2004, when it replaced the original PTFE material seal.

The modified PTFE seal provides these benefits over the previous verision:

Lower porosity and permeability

Fewer void spaces

Higher elasticity

Reduced deformation under load

Better chemical resistance to controlled media

Smoother surface and improved design flexibility

The standard bonnet seals consist of 2 'V'-shaped FKM gaskets and a package of 25% graphite-filled PTFE gaskets.

You can read more on our Angle Seat Piston Valves and 10 Reasons to use them here.

Process Solenoid valves

Solenoid valves are simple and effective electrically operated valves to control liquid, gas or steam. Solenoid valves have many uses, from controlling compressed air to operate pneumatic equipment, controlling high pressure oil to operate hydraulic equipment.

A solenoid valve that controls the actual media would generally be considered a process valve.

A solenoid valve can be used in a wide range of environments to control a multitude of media.The important consideration is that the correct solenoid valve must be selected.

Ambient temperatures can range from sub zero conditions such as in a refrigeration unit to desert like conditions. We must consider the pressure parameters, the media temperature ranges, frequency of operation, they may even be used in a highly explosive environment like a flour mill or an environment containing combustible gasses.

Selecting the right valve for the application requires a great level of skill and experience.

In order to select the correct solenoid valve for an application we would need to collect all the technical data, such as: the media, the pressure, the differential pressure, the temperature, the voltage available, the environment, the frequency of operation.

All of these factors would affect which solenoid valve is selected.

The basic principals of a solenoid valve.

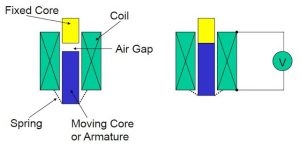

The principal of a solenoid valve uses a copper wound coil over an armature housing a fixed core and a moving core. When the coil is electrically energised the moving core is attracted to the fixed core.

When coil is energised, the armature is attracted to the fixed core, the spring is compressed and the valve is opened allowing flow. Lifting the armature to the fixed core consumes more power than holding the armature, this is referred to as the inrush and holding power.

The inrush is the power required to lift the armature and the holding is the power required to hold the armature in place.

The armature is made of a specific grade of stainless steel,1.4105 EN (AISI 430F). This grade of steel is magnetic and also suitably erosion resistant.

You can read more on Solenoid Valves here.

M&M Solenoid and Piston Valves

M&M International (UK) Ltd. are the sole UK distributors of M&M International, manufacturers of solenoid valves and pneumatic angle seat piston valves. M&M International products are widely recognised in the process industry as reliable, high-quality valves that remain competitively priced.

Our extensive range of products cover a multitude of applications; making M&M International an industry leading supplier of solenoid operated process control valves and pneumatic piston valves.

Technical advice

Please feel free to contact our experienced technical team for advice and assurance of the right valve solutions for your specific requirements.

Ordering

From supplying a single valve or spare part to the design of bespoke valve solutions for original equipment manufacturers, M&M International can help.

We offer most standard products from our extensive stock holding and dispatch within the UK Next Day.

Contact us

If you wish to discuss your application and requirements, please contact our experienced team of engineers on 01234 855888 , email us on sales@mmint.co.uk, or use the contact form below.