Solenoid Valve Guide: Part 3

In Solenoid Valve Guide: Part 3, we are going to be looking at the different types of solenoid valves and their modes of operation, giving different examples of the variations of solenoid valves available. We will also discuss the various coils and enclosures, their IP ratings and other features available with them.

Solenoid valve types and modes of operation;

Modes of operation;

Valve Selection;

A solenoid valve should be chosen if any of the following circumstances are met;

- Media without particles

- Moderate flow volumes

- Average differential pressures

- High speed in operation

- Media with a viscosity not higher than 21 cST (3°E)

2/2 N/C Normally Closed Solenoid Valve

2 way, normally closed, energise to open, on/off operation (de-energise to close), with one inlet and one outlet connection.

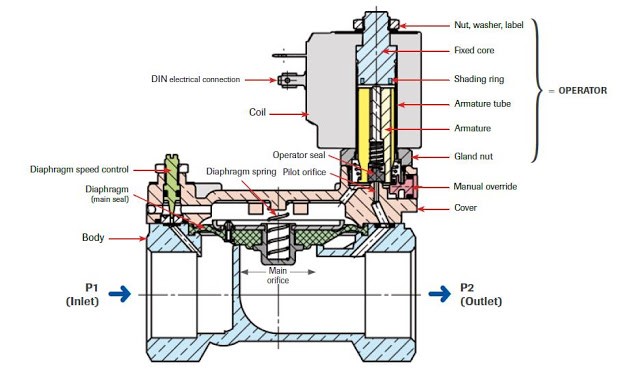

There are two types of valve operation – direct acting and pilot operated

a) Direct acting – The coil supplies all the power to open the valve and the valve will operate from zero pressure.

b) Pilot operated – This can either be diaphragm or piston operated. These valves have a pilot hole which is opened/closed by the coil acting upon a plunger and diaphragm or piston used to control the

main orifice. This operation relies on the media pressure difference between the inlet and outlet and a minimum operating pressure is required to operate these valves unless stated as zero.

dapibus leo.

2/2 NO Normally Open Solenoid Valve

2 way, normally open, energise to close, de-energise to open, with one inlet and one outlet connection. Can either be direct acting or pilot operated.

3/2 N/C, Normally Closed, Solenoid Valve

Valve open when energised, closed when de-energised. This valve operates on the same principle as the 2/2 N/C version except the valve has 3 connections, 2 orifices, one permanently open, one permanently closed. The use of these is for the operation of actuators for large valves where a single cylinder spring return system is employed.

3/2, N/O, Normally Open, Solenoid Valve

Valve open when de-energised, closed when energised.

3/2 UNI, Universal, Solenoid Valve

The valve may be used as normally closed, normally open or diversion/selector valve.

5/2 Solenoid Valve

These valves are available in 2 forms;

A) Single solenoid – 2 positions, spool and sleeve type, which is based on an air pilot return mechanism. When de-energised, the valve allows one inlet and one outlet to be connected, exhausting the other inlet/outlet connection through an exhaust port. On energisation, the action reverses.

B) Dual solenoid valves – these spool and sleeve type solenoid valves are momentary contact type. When one coil is energised, one inlet is connected to one outlet, with the other inlet/outlet connection connected to an exhaust port, when the coil is de-energised and another coil is energised, the action is reversed.

These valves are for use on double acting cylinder applications.

![]()

2/2 N/C, Normally Closed, Pneumatic

2 way, normally closed, pressurise to open, de-pressurise to close with the aid of a return spring, having one inlet and one outlet connection. Can be direct acting air operated against a return spring.

Note: These valves are operated via a 3-way solenoid valve which is always required.

2/2 N/O, Normally Open, Pneumatic

2 way, normally open, pressurise to close, de-pressurise to open with the aid of a return spring, having one inlet and one outlet connection. Can be direct acting air operated against a return spring.

Note: These valves are operated via a 3-way solenoid valve which is always required.

2/2 N/C, Normally Closed, Motorised

2 way, normally closed, energise to open – (slow opening) de-energise to close – (quick closing) with one inlet and one outlet connection. Motor-driven against a return spring.

2/2 N/O, Normally Open, Motorised

2 way, normally open, energise to close – (slow closing) de-energise to open – (quick opening).

2/2 N/C, Normally Closed, Manual reset (Solenoid)

These valves operate on the same principle as 2/2 N/C direct-acting version except – once the coil is energised the valve will not open until manually opened by either a lever or push reset device.

2/2 N/C, Normally closed, Manual reset (Motorised)

The operation is similar to 2/2 N/C normally closed manual reset (solenoid) except, once the motor is energised the valve will not open till a manual reset/relay button is operated, either remote or integral to the actuator. General use is for both manual reset or safety systems where knowledge of an electrical failure is required.

Coils;

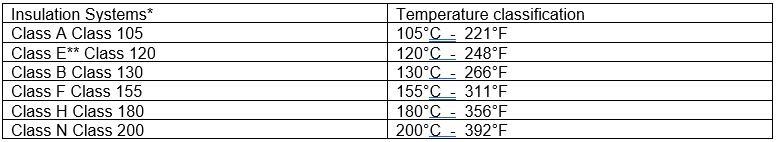

Copper winding temperature classification;

Insulation systems are arranged in order of their insulation level and classified by a letter symbol or by a numerical value.

The numerical value relates to the temperature classification of the insulation system.

The temperature classification indicates the maximum (hotspot) temperature at which the insulation system can be operated for normal expected service life.

In general, all materials used in a given insulation system should be rated for temperatures equal to, or exceeding, the temperature classification of the system.

* IEEE Std. 117.

** Used in European Equipment.

Solenoid Enclosures;

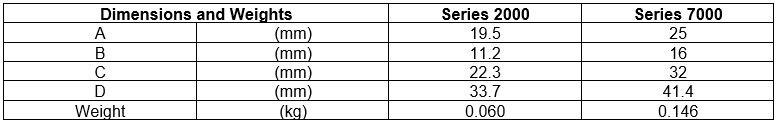

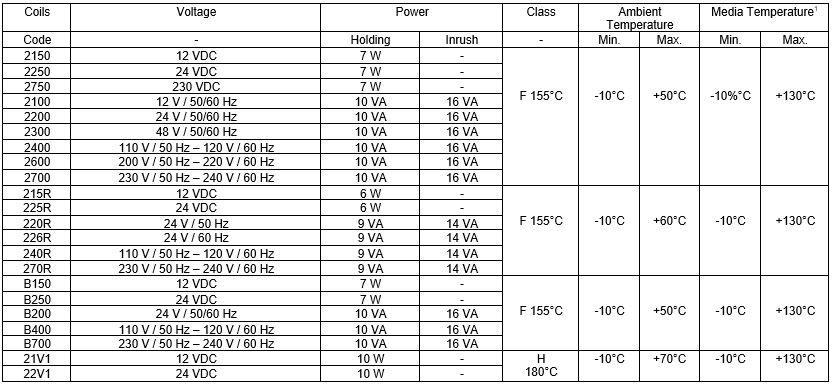

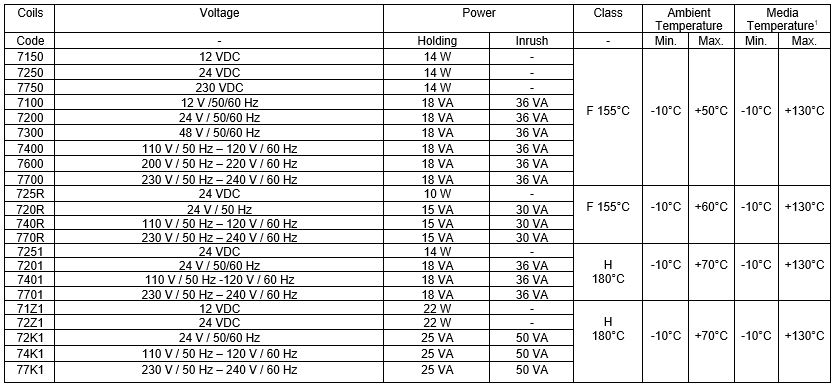

Series 2000 and Series 7000

Coils in this series are designed for continuous duty in conformity to the EN 60730 safety standards.

They are encapsulated in a self-extinguishing synthetic material and offer high mechanical protection and excellent thermal dissipation.

They are fully interchangeable on all our solenoid valves, but we would recommend talking to our technical team for more info.

Common Features;

Electrical connection: Fast on connection 6.3 x 0.8

Protection class: IP 65 (according to EN60529) – NEMA 4 (UL 50) with connector and gasket

Operation: Continuous (ED 100%)

Voltage tolerance: - AC +10% ÷ - 15% / - DC +10% ÷ -5%

Notes:

All coils are manufactured in accordance with:

RoHS Directive (2011/65/EU)

Insulation class according to EN 60730-1 see the table below

All windings are realised with class ‘H’ wires (180°C)

1 - Some valve configurations allow a max. fluid temperature up to 180°C, please check valve data sheets.

Solenoid Enclosures

E5 Type Enclosure

Protection Class IP65

External Material: Glass-reinforced nylon

Electrical Connection: DIN Plug to ISO 4400

Winding insulation: Class H

Enclosure conforms to IP65 when correct plug gasket is fitted as supplied.

S20 Type Enclosure

Protection Class IP65

Material: Pressed Steel

Electrical Connection: DIN Plug to ISO 4400

Winding insulation: Class H

This enclosure conforms to IP65 when correct plug seat gasket is fitted.

S4 Type Enclosure

Protection Class IP50

External Material: Pressed steel Powder Coated

Electrical Entry: Conduit boss 20mm or ½” NPT

Electrical Connection: Screwed terminals or 0.5mm flying leads, or Din connector for cryogenic applications

Winding insulation: Class H

S7 Type Enclosure

Protection Class IP65

Material: Nylon

Electrical Connection: DIN Plug to ISO 4400

Standard Enclosure for Universal Namur Valves

Winding Insulation: Class F

This enclosure conforms to IP65 when correct plug seal gasket is fitted as supplied.

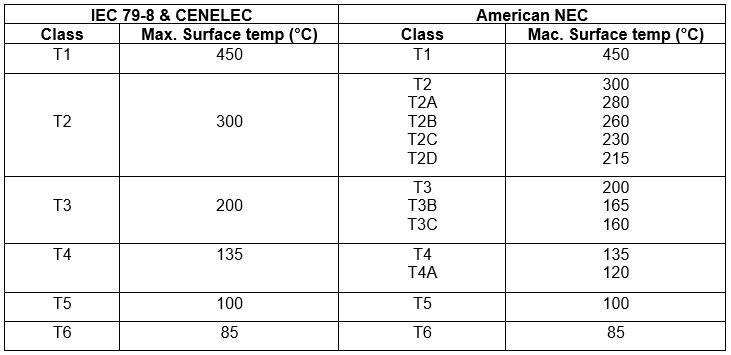

Explosion-proof / Weatherproof

Enclosure S4 type Exd ATEX or IECEx / CSA / cCSAus approved.

Intended for use in potentially explosive atmospheres directive 2014/34/EU.

Compliance with essential health and safety requirements EN60529 (IP67), EN60079-0.

Features;

Special purpose solenoid valves are used for controlling gases or liquids where a potentially explosive gas/air mixture is present in the atmosphere for long periods or likely to occur in normal operation.

Flameproof enclosures are suitable for hazardous areas Zone 1 and Zone 2, for the control of Group IIA, IIB, IIC gases.

Application;

Valves configured for hazardous areas

User to consult all applicable codes, such as N.E.C., EU directive 99.92/EC, for definitions, performance and safety requirements associated with Hazardous Area Classification, Apparatus Group, Zones,

Division and Temperature Classification.

Protection class; II 2 G Exd IIC T6 for ambient temperatures -50°C to +40°C

Optional; II 2 G Exd IIC T4 for ambient temperatures -50°C to +70°C

Certificate No.; Sira 03ATEX1319 (ATEX) IECEx CSA 07.0002 1676463 (CSA cCSAus)

Weatherproof to IP67

Technical Specification;

Power consumption; Holding – 19 VA, 12 V to 230 V 50 / 60 Hz. 14.5 W 12 V to 212 VDC

Material; Power coated Aluminium or 316 St. St enclosure with St. St nameplate

Electrical Entry; M20 x 1.5 or ½” NPT Conduit Entry

For more information on compatibility please contact our technical team.

Explosion-Proof / Weatherproof

Enclosure S4 Type Exd ATEX or IECEx approved

Intended for use in potentially explosive atmospheres Directive 2014/34/EU

Compliance with essential health and safety requirements EN60079-0 and EN60079-18

Features;

Special purpose solenoid valves are used for controlling gases or liquids where a potentially explosive gas/air mixture is present in the atmosphere for long periods or likely to occur in normal operation.

Flameproof enclosures are suitable for hazardous areas Zone 1 and Zone 2, for the control of Group II gases.

Application;

Valves configured for Hazardous Areas.

User to consult all applicable codes, such as N.E.C., EU directive 99/92/EC, for definitions, performance and safety requirements associated with Hazardous Area Classification, Apparatus Group, Zones,

Division and Temperature Classification.

Protection Class; II 2 G Exm II T5 for ambient temperatures -20°C to +40°C

Hazardous area certificates; Baseeda06ATEX0302X (ATEX) IECEx BAS06.0080X

Weatherproof to IP65

Technical Specification;

Power consumption; Holding – 16 VA, 12 V to 230 V 50 / 60 Hz. 10 W, 12, 24 VDC.

Material; Powder coated metal enclosure with stainless steel nameplate.

Electrical Entry; 2 Metre length of approved 3 Core cable with M16 conduit male winding insulation class.

Intrinsically safe enclosures (ATEX approved)

Complies with EN60079-0 and EN60079-11

Protection Class; Exia IIC T6, ATEX approved for ambient temperatures -40°C to +50°C

Maximum valve media temperature of 70°C

Certificate No.; PTB 02 ATEX 2154

Weatherproof to IP65

Technical Specification;

Winding insulation; Class F

Rated Voltage; 24 VDC with typical 300 ohm Zener barrier

Max Power Consumption; Exia 1.6 watts DC

Material; Thermoset resin

Electrical Entry; PG9 via Din Plug Connector Din 43650-A

Explosion-proof / Weatherproof

Protection class; EEx m II 2GD T4

Certificate No.; PTB 03 ATEX 2086 X, IECEx PTB 05.0005X

Weatherproof to IP65

Technical Specification

Winding insulation; Class F

Material; Thermoplastic

Electrical Entry; 3 m wired cable, with ferrules.

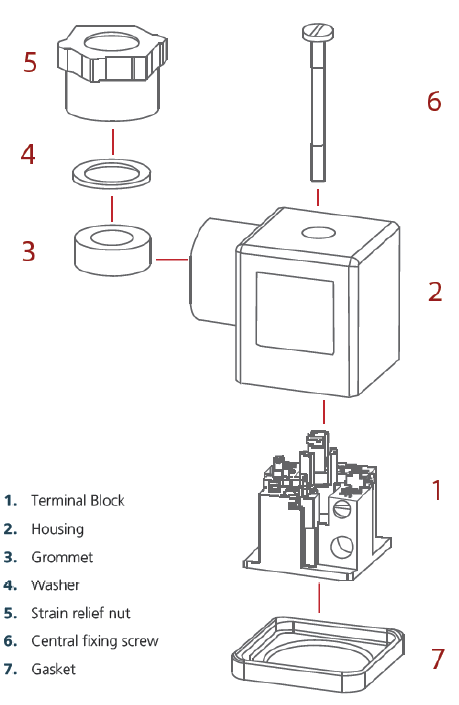

Din Connectors;

Features;

- Dust and splash proof protected (IEC60529-IP65)

- Impact resistant plastic housing

- Easy to install cable harness

- Optional integrated electronic circuit, optional indicator LED with or without rectifiers etc.

- Retained central fixing screw.

- Special versions may be available, please contact our technical team.

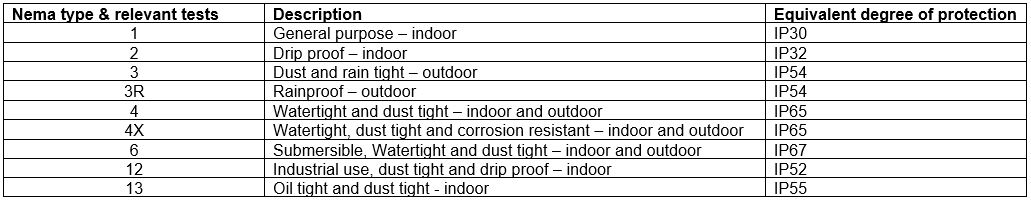

Protection Class, IP ratings & Hazardous Areas

IP Ratings

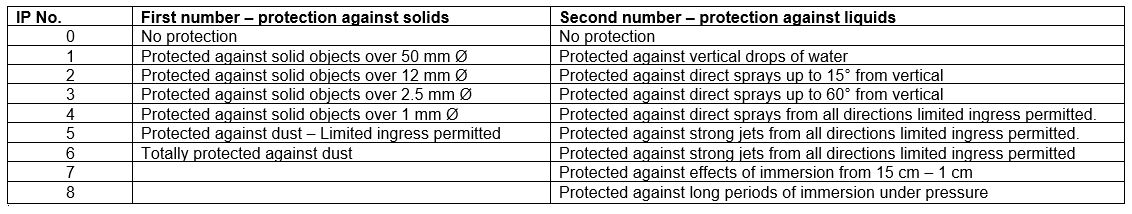

International standards – temperature classification

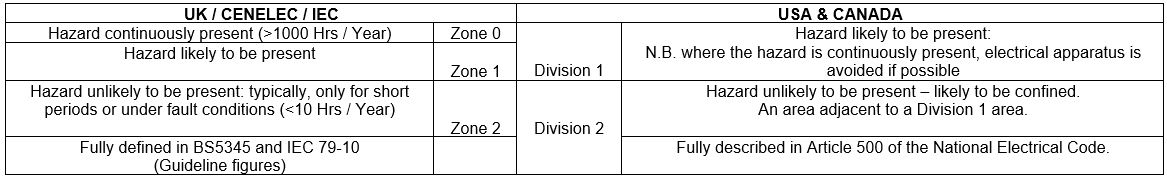

Zones & Divisions – Define the likelihood of the hazard being present in a potentially explosive concentration