Ironing Boards

Integrated industrial ironing boards for the final finishing of clothing. The appliance is equipped with iron, vacuum blow table and sleeve form board.

Ironing boards, utility presses and spotting tables make up an ironing group for various operators. Each machine can be self contained or connected to a steam, vacuum and compressed air set.

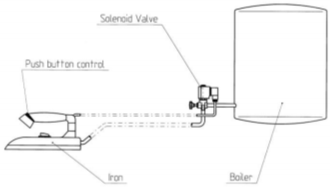

Construction Diagram Of The System

Solenoid Valve application

View our full range of Solenoid Valves

The system exploits steam to ease the ironing of clothing. The iron is equipped with a push button control that supplies steam on the cloth when pressed.

The solenoid valve installed on the ironing board controls the steam produced by an electric boiler and sends it to the iron when the push button control is operated.

The solenoid valve is fitted with a flow regulator (screw or knob) that enables the operator to regulate quantity and pressure of steam to be applied on the garment being ironed.

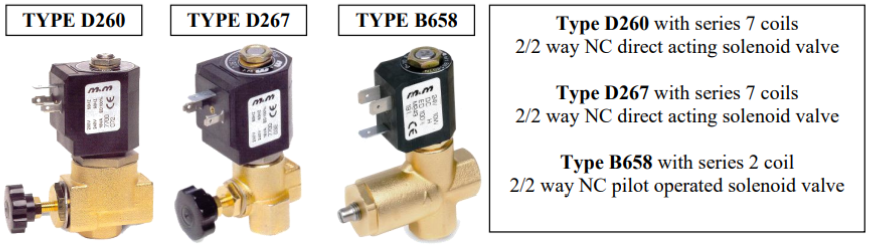

Solenoid Valves Used

You can buy M&M International Solenoid Valves online through the V-Flow Solutions web shop

A solenoid valve capable to withstand many cycles every day is needed for this application.

The three types we recommend are all compatible with the requested application but have different features.

Valve D260 has a very large orifice (6 mm) but the maximum pressure is 5 bar - 150° C.

Valve D267 has an orifice of 3 mm or lower but can reach 180° C -10 bar; the standard seal is Rulon and the coil is class H. Therefore it is suitable for exacting industrial applications.

The valves last longer and are more robust compared to alternatives.

M&M also has type B658, operating with a piston, with a PTFE seal guaranteed for 5 million cycles at 10 bar – 180° C.

If you would like to speak to a member of our technical team regarding the solenoid valves above, or to create a bespoke unit for your application call us on 01234 855888 or send us an email