Introduction to solenoid valves

Solenoid valves are simple and effective electrically operated valves used to control the flow of liquids or gas.

A solenoid valve can be used in a wide range of environments to control a multitude of media. They are used in a variety of applications, such as controlling compressed air used to operate pneumatic equipment, controlling high-pressure oil used to operate hydraulic equipment, industrial automation, sterilization systems, cooling systems, industrial vacuum packaging and many other processes.

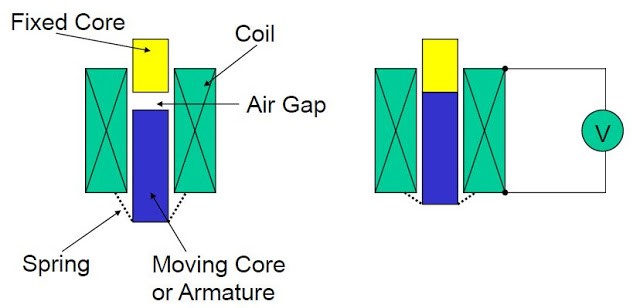

A solenoid valve consists of the valve body, a wound copper solenoid coil, an armature tube containing a fixed core and a moving core (known as the armature or plunger) and, in some valve types, a diaphragm. The armature is fitted with a spring and a seal. When the coil is energised the electromagnetic force created is used to move the armature either towards or away from the fixed core. This movement enables the control of the flow of the media through the valve body.

The solenoid coil produces the electromagnetic force required to operate the valve. It consists of a winding of copper wire encased in a self-extinguishing synthetic material. The electrical supply is connected to terminals on the side of the coil. For safety purposes this connection is usually made through a DIN connector plug and gasket.

When the coil is de-energised the valve is known as either normally closed (NC) – the valve remains closed until the coil is energised, or normally open (NO) – the valve remains open until the coil is energised.

As well as the standard 2 port function (known as 2/2 way) type of valve which has only one flow passage from the inlet to the outlet connection, some solenoid valves are also available with 3-way configurations (known as 3/2 way) which have 3 connections and 2 flow passages. These can be normally open, normally closed, diverting or mixing.

There are three standard types of solenoid valve:

You can view the M&M International UK range of Solenoid Valves here

Direct acting – The seal contained in the armature acts directly upon the valves main orifice to control the flow of the media. Direct acting valves can operate with zero differential pressure and have a fast average response time of 5 to 25 ms. They are available as 2/2 way or 3/2 way and normally closed or normally open.

Pilot operated – A minimum inlet differential pressure is required to act upon a diaphragm to produce the necessary force to open and close the valve. Higher fluid volumes and pressures can be controlled with pilot operated valves. Available as 2/2 way and normally closed or normally open.

Pilot operated with assisted lift – These are similar to pilot operated valves except the armature is mechanically connected to the diaphragm. At lower pressures they operate the same way as direct acting valves but at higher pressures they act as a pilot operated valve would. Only available as 2/2 way and normally closed.

As an example of the basic operating principle of a solenoid valve, in a standard direct acting 2 port (2/2 way) normally closed (NC) valve when the coil is electrically energised the electromagnetic force created attracts the moving core to the fixed core, the spring around the moving core is compressed allowing the armature and seal to move away from the valve orifice as shown in the diagram below. The valve is now open allowing the media to flow through the valve body. When the coil is de-energised the force of the armature spring returns the armature and seal to the valve orifice.

In a standard direct acting 2 port (2/2 way) normally open (NO) solenoid valve the armature and fixed core are reversed and the spring holds the armature away from the orifice. When the coil is energized the plunger and seal moves onto the valve orifice sealing the valve and stopping the flow of the media.

Valve bodies are usually constructed from brass or stainless steel although other materials such as plastic or nickel plated brass are often used.

Armature tubes, armatures and valve orifices are usually constructed from stainless steel.

Armature seals, diaphragms and o-rings are made from a variety of materials. These include the rubbers NBR, EPDM and FKM. For more heavy duty applications materials such as PTFE, Sigodur, Ruby and Kalrez are used.

If you would like to purchase M&M Solenoid Valves online, please visit our web shop

Alternatively, you can contact our technical team by:

Phone: 01234 855888

Email: sales@v-flowsolutions.co.uk