Standard Solenoid Valve Types

Pilot Operated Solenoid Valve

Pilot operated solenoid valves are available as 2/2 way and either normally closed or normally open.

You can view the full range of M&M International UK Solenoid Valves here

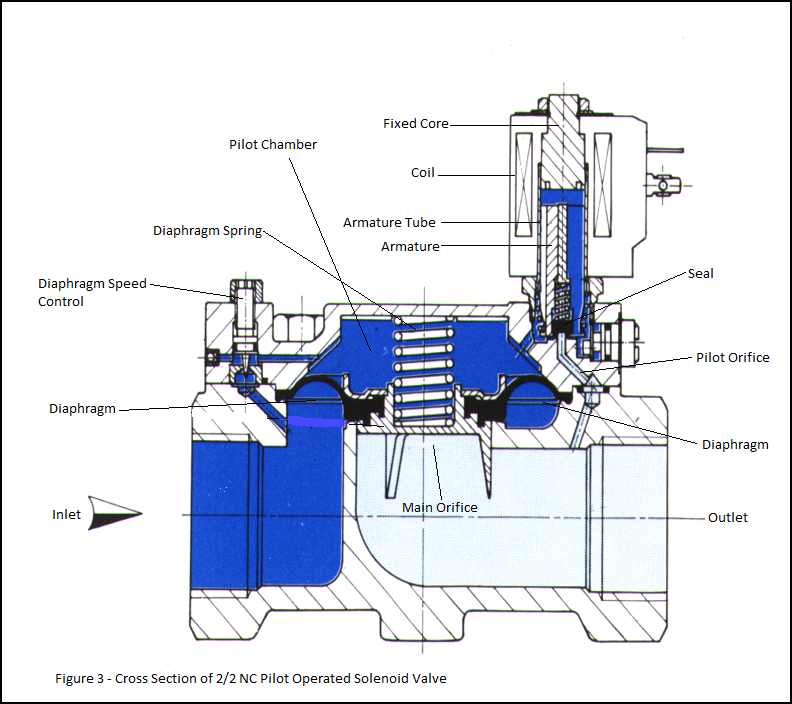

Figure 3 shows the cross section of a normally closed 2-way pilot operated solenoid valve (2/2 way NO). The valve body is divided into two chambers by a diaphragm – a pilot chamber above the diaphragm and an operating chamber below.

The media flows from the inlet (through a small bleed hole in the diaphragm or valve body) to the pilot chamber above the diaphragm. When the coil is de-energised, the pressure of the media acting on the upper surface of the diaphragm, combined with the force of the diaphragm spring, is greater than the pressure acting on the lower surface. This results in the diaphragm being held closed onto the main orifice preventing the flow of the media. When the coil is energised the armature seal is lifted from the pilot orifice allowing pressure to be released from the pilot chamber.

The pressure in the operating chamber is now greater than that in the pilot chamber causing the diaphragm to lift and allowing the media to flow under the diaphragm to the outlet connection. When the coil is de-energised the process is reversed - the pilot orifice is sealed and the pressure in the pilot chamber builds until it is sufficient to close the diaphragm onto the main orifice.

In the normally open version (2/2 way NO) when the coil is energised the pilot orifice is sealed by the armature and so the pressure above the diaphragm becomes greater than below thus closing the main orifice.

Pilot operated valves will not operate without a minimal inlet pressure (usually around 0.3 to 0.5 bar) and a minimal pressure differential from inlet to outlet is required for the valve to function correctly. Differential pressure is calculated by subtracting the outlet pressure from the inlet pressure (P = P1 - P2).

Pilot operated solenoid valves can operate at much higher pressures than direct acting valves and also provide higher flow rates. Their average response time is 50 – 500ms. They can also be supplied with a diaphragm speed control which regulates the closing speed of the diaphragm and is used to prevent the effects of waterhammer. As with direct acting valves, manual override is available on some pilot operated valves.

You can purchase solenoid valves online through the V-Flow Solutions web shop