Solenoid Valve Guide: Part 5

In this part, we are going to be talking about some example applications that we have supplied solenoid valves for.

These are not the only applications that these solenoid valves can be used for, but we have seen valves being used in these applications in our experience.

Here is the full list of solenoid valve applications in PDF form:

All of the application PDF’s can be found here.

Here are a select few applications that we have decided to describe.

Solenoid Valve Applications;

Solenoid valves in air compressors

One of the applications we see solenoid valves in is Air compressors. (can use the title application as a link to PDF)

The way a solenoid valve will work in the compressor is as follows;

When the system is operating, the electric motor runs the compressor, which takes in filtered air, compresses it, sends it to the refrigerator and finally to the tank.

During this stage, the solenoid valve is energised and closes the circuit keeping it under pressure.

When the tank reaches the requested pressure reading, a pressure switch stops the motor and the check valve keeps the air inside the tank.

To prevent the compressor from remaining under pressure for too long and so getting damaged, the solenoid valve is then de-energised, and it allows exceeding air still in the circuit to be exhausted.

There are three variants of solenoid valves that we have seen used in this application, the RD236, the RB214 and the RB 203.

The RD236 and RB214 are direct acting solenoid valves whilst the RB203 is a pilot operated solenoid valve.

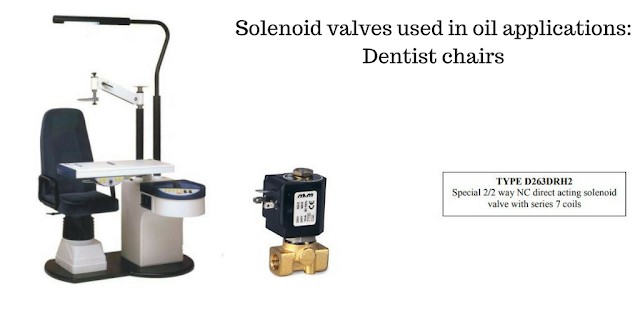

Solenoid Valves in Dentist Chairs

Integrated station with all the necessary dental or ophthalmic equipment, complete with automatic chair and adjustable lamp. All automatic functions are easily run by the operator through a console.

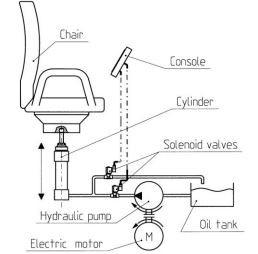

The chair lifting system works under the thrust of a hydraulic cylinder operated by the medium (oil). Compared to a mechanical system, the hydraulic trust has the advantage of a “Smoother” movement.

Two solenoid valves are used in this application to regulate the height of the chair.

Oil is taken from the basin by the pump and let into the circuit at a pressure of 12-13 bar.

When a button is pressed on the console, the solenoid valve is operated; it intercepts oil in the pumps and sends it to the cylinder.

The cylinder enables hydraulic energy to be turned into mechanical energy thus lifting the chair to the desired height.

By pushing another button, the second valve opens.

Under the effect of the overhanging weight, oil under pressure inside the cylinder is exhausted into the basin, and the chair is pushed down.

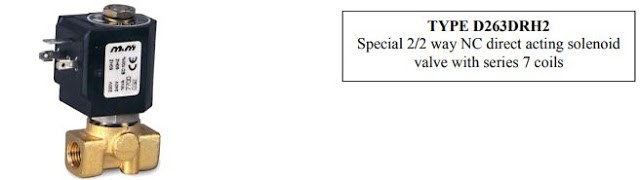

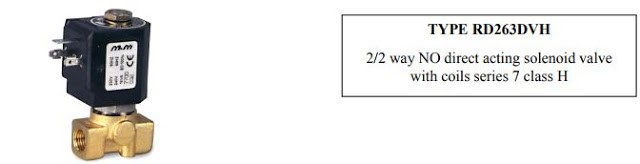

The most prevalent solenoid valve we see used in this application would be:

A special version of valve D263 is recommended for this application.

Unlike the standard valve, it is equipped with a cone-shaped spring on the plunger, with a heavier load.

With this option, the fixed core and plunger do not stick due to the viscosity of the medium when the valve closes (i.e. when the coil is de-energised).

The plunger is equipped with a Ruby seal to guarantee very high performance.

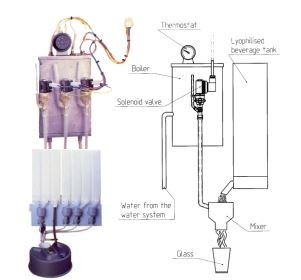

Solenoid valves in automatic hot drinks dispensers

Hot drinks dispensers are made to distribute coffee, tea and other hot drinks quickly and are usually placed in public areas, work offices or private facilities.

Vending machines for espresso or lyophilised coffee and soluble hot beverages.

The main feature of vending machines consists in a quick distribution of coffee, tea, milk and chocolate in working places, public or private facilities (offices, factories, hospitals, schools, bars, restaurants, etc.).

Vending machines usually consist of two supplying groups, one for coffee and one for soluble beverages,

This image describes the operation of the group for soluble beverages and specifically the use of vending valves with media at atmospheric pressure.

The sequence of distribution is the following;

First the plastic glass is positioned, then sugar is supplied and finally, the beverage and the coffee spoon are delivered.

When the user selects the product on an electronic push-button panel, the infusion process is activated.

A volumetric dispenser prepares a single-dose of powder into the mixer.

Hot water at a temperature of 90-95°C is delivered from the boiler to the mixer by a vending valve.

The level of water inside the boiler is kept constant by an electronic system letting in fresh water from the water supply whenever it is necessary.

Finally, the mixer exploits the centrifugal force to dissolve the powder in water and so obtain the beverage.

After the mixing operation, the mixer stops, and the beverage is delivered into the glass by gravity.

The types of solenoid valves commonly used in hot drinks dispensers are;

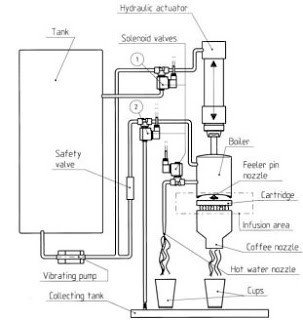

Solenoid valves in coffee-in-cartridge dispensers

Coffee-in-cartridge dispensers are used to provide coffee and other hot beverages from cartridges, these are usually semi-automatic.

Semi-automatic coffee-in-cartridge dispensers complete with hot water delivery heads are used to supply coffee and soluble beverages in a cartridge.

The hydraulically moved coffee infusion unit automatically expels the cartridge into the specially provided container.

The dispenser can be equipped with a support cabinet with a cup dispenser, spoon and sugar drawer and product storage compartment with a door.

Small dimensions and easiness of use make them widely used as household appliances but also in shops, offices, associations, laboratories, hotels and wherever a constant supply is not required.

Water contained in a tank is sucked up by a vibrating pump and then intercepted by two 3-way solenoid valves.

The former supplies the hydraulic actuator, the latter delivers water to the boiler. The boiler is always full of hot water whose temperature is adjusted by a thermostat.

It is installed on the actuator stem and is equipped with a feeler pin nozzle that delivers hot water when it is pressed.

The operation starts when the cartridge is in;

The two solenoid valves open at the same time and the actuator pushes the boiler downwards against the cartridge.

A safety valve above the second solenoid valve prevents water from flowing out before the actuator has descended completely.

When the pressure of 9-10 bar has been reached inside the circuit (about 10 sec), the safety valve opens, cold water flows into the boiler while water that had previously been warmed up flows out and filters through the cartridge.

The mixture produced (coffee, tea, chocolate, cappuccino, etc.) flows through a nozzle into the cup.

At the end of the cycle, the second solenoid valve closes and exhausts the remaining hot water under over-pressure from the third way into the collecting tank. Then the first solenoid valve closes and water under pressure inside the actuator is exhausted from the third way into the tank.

The actuator returns into its rest position under the effect of the spring.

When a different control is selected, only hot water is delivered; a two-way solenoid valve connected directly to the boiler intercepts hot water and pours it directly into the cup through a different nozzle.

The types of solenoid valves typically used in this application are:

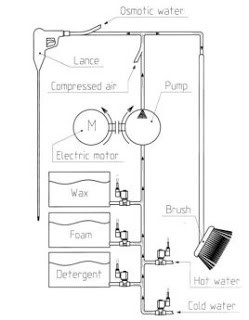

Solenoid valves in car washing systems

Self-service car washing systems are an innovation in the car washing field; there are self-service washing areas for cleaning vehicles like scooters, motorcycles, camper vans, caravans, small boats and all-terrain vehicles that cannot be cleaned in tradition car washing systems with brushes.

The system delivers high-pressure water mixed with wax, detergent and car washing foam through a lance and a brush.

The user selects a cleaning cycle on the control panel and cleans the vehicle using two basic tools; a lance and a brush.

While the vehicle is being rubbed, the brush pours liquid detergent to remove dirt.

During the shampooing cycle, two solenoid valves let cold and hot water into the circuit.

Three more solenoid valves inside the circuit intercept liquid detergent, foam and wax respectively and mix them with water.

An electromechanical pump sucks up the mixture by depression and lets it back into the circuit at 80 bar.

Before reaching the brush, the liquid is further mixed with air.

The lance is a washing gun shooting either water or shampoo under pressure, according to the selected cleaning cycle.

Usually, water used for rinsing is softened and osmotic, a treatment that prevents white limescale from staining the vehicle.

The solenoid valve used in this application is;

In this application, the solenoid valve carries out various functions.

The body is nickel coated so as to protect brass against corrosion when detergents flow through it.

Solenoid valves in vacuum packers

Another application we see solenoid valves used for is in vacuum packers.

A vacuum packer is used to vacuum pack food in a different environment.

This would be useful for supermarkets or butchers.

Food is vacuum packed to prolong its preservation.

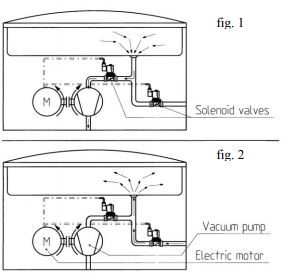

Foodstuffs inside plastic bags are blocked by the transparent bell. The bell is lowered, and the vacuum cycle starts when a button is pressed.

The air inside the chamber is sucked up by the pump as indicated by arrows (fig 1); vacuum is generated and the plastic bag sticks to the product; an edge of the bag is then sealed.

When this operation is over, the atmospheric pressure in the packing chamber is restored (fig 2) and the bell is opened.

Two solenoid valves are employed in this application for the vacuum cycle.

The former allows the pump to suck up air from the chamber and keep the vacuum in the room when the sucking up operation is over.

The latter restores the atmospheric pressure after the packaging has been sealed.

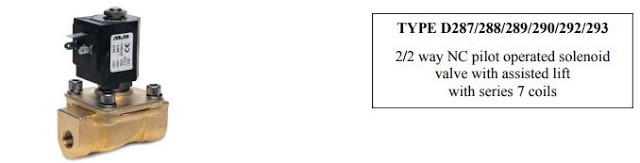

The type of solenoid valve that would be used in this application is;

Solenoid Valves in refrigerant loading systems

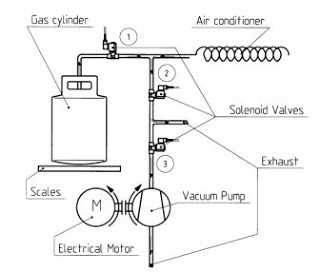

A refrigerant loading system is used to replace refrigerant gas in refrigeration systems.

The unit will carry out a vacuum cycle followed by a loading cycle; it automatically checks vacuum signalling even for small leaks in the system, then quickly loads the refrigerant without the risk of a mistake.

The system is designed for three NC solenoid valves; (1) for loading the refrigerant, (2) on the vacuum line, (3) in the intake line of the vacuum pump (vacuum test).

In the vacuum cycle, solenoid valves 2 & 3 open and the pump takes in remnant gases from the air conditioner and lets them into a disposal container.

Once the vacuum cycle is over, solenoid valves 2 & 3 close, the pump stops and solenoid valve 1 opens.

Now the loading cycle begins and the refrigerant flows from the cylinder into the circuit of the air conditioner under the effect of vacuum.

Thanks to the electronic scales the system will load the exact quantity of gas that had been previously taken.

The type of solenoid valve that would be used in this application is;

Solenoid valves in exposure units

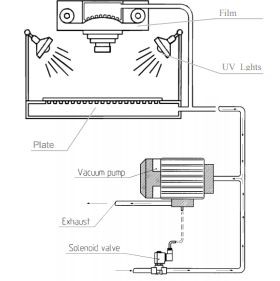

Exposure units are machines designed for the printing and silk-screening fields and used for exposing pre-sensitised aluminium plates.

The machine works on the images imprinted on films and reproduced on the plate.

An operator mans this machine by laying the plate on the carpet and, after closing the glass holding frame, pushes the start button on the control panel.

The exposure unit is equipped with a microprocessor to carry out the complete working schedule automatically;

Preheating of the lamp, pre-vacuum, vacuum, selection of the lamp power, main and secondary exposure, masking, switch-off of the lamp, re-establishment of the pressure.

The solenoid valve and the vacuum pump are responsible for the cycle of creating a vacuum inside the unit.

When the pump is on, the normally open solenoid valve is energised and close the circuit, keeping vacuum inside the unit.

At the end of the exposure, the pump stops, and the solenoid valve is de-energised, opening the circuit to the outside and thus restoring the atmospheric pressure inside the unit.

The type of solenoid valve that would be used in this application is;

You can view all of our listed Solenoid Valve applications here.

If you have missed any parts in the solenoid valve guide, you can check here for all the available parts.

If you have any questions or queries you would like to discuss, please contact our technical team on: 01234 855888 or email: sales@v-flowsolutions.co.uk to get in contact.