Hot Drinks Dispenser

Vending machines for espresso or lyophilised coffee and soluble hot beverages. The main feature of vending machines consists in a quick distribution of coffee, tea, milk and chocolate in working places, public or private facilities (offices, factories, hospitals, schools, bars, restaurants, etc.). Vending machines usually consist of two supplying groups, one for coffee and one for soluble beverages. This sheet describes the operation of the group for soluble beverages, and specifically the use of vending valves with media at atmospheric pressure.

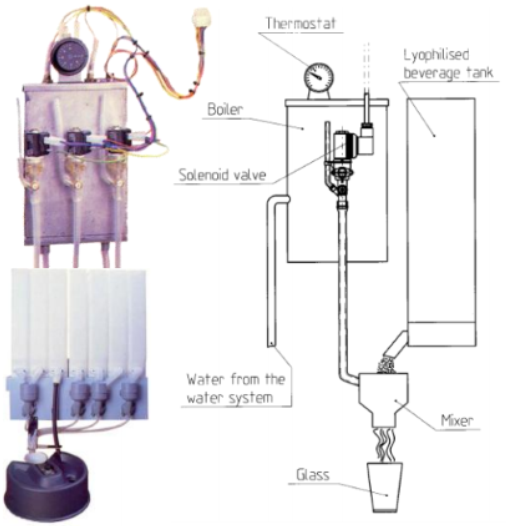

Construction Diagram of the System

Solenoid Valves in Hot Drinks Dispenser Applications

View our full range of Solenoid Valves

You can buy M&M International Solenoid Valves online through the V-Flow Solutions web shop

The sequence of distribution is the following: first the plastic glass is positioned, then sugar is supplied and finally the beverage and the coffee spoon are delivered. When the user selects the product on an electronic push-button panel, the infusion process is activated. A volumetric dispenser prepares a single-dose of powder into the mixer. Hot water at a temperature of 90-95°C is delivered from the boiler to the mixer by a vending valve. The level of water inside the boiler is kept constant by an electronic system letting in fresh water from the water supply whenever it is necessary. Finally, the mixer exploits the centrifugal force to dissolve the powder in water and so obtain the beverage. After the mixing operation, the mixer stops and the beverage is delivered into the glass by gravity.

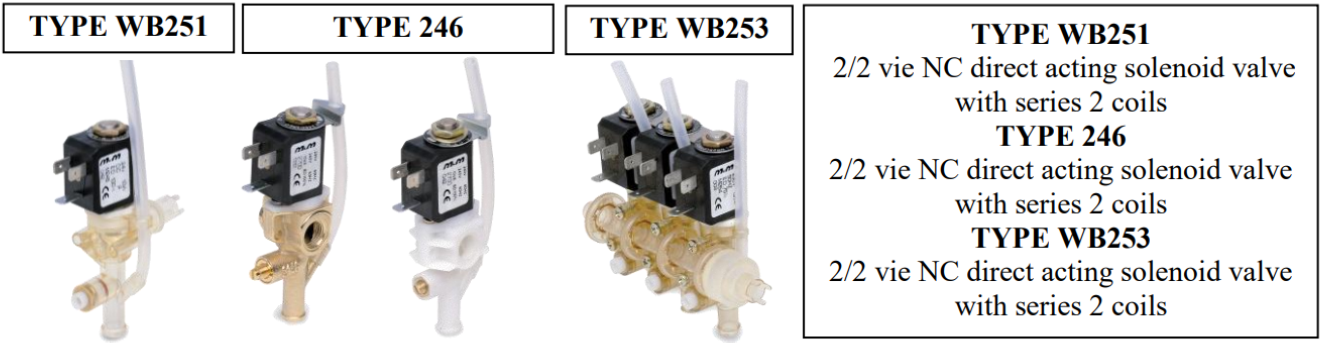

Recommended Solenoid Valves

The recommended valves are the best offered on the market in the vending field. M&M was created and developed with a specialization in this application and, unlike less qualified competitors, we propose a wide range of products designed to satisfy customers’ requests. These solenoid valves work on the principle of medium falling by gravity and therefore they can work only when they are positioned vertically. Features common to all models are the flow regulation screw and the dry armature; the total lack of contact between the beverage and the internal parts of the valve guarantees the highest level of compatibility with foodstuff. Except for type WB251, types 246 and WB253 can be assembled as manifolds to differentiate the quantity supplied (ex. espresso or weak black coffee). The most widely used material for the valve body is polysulfone, a plastic compatible with foodstuff and with a high resistance to heat, but in some applications brass as for type 246 is more appropriate.

If you would like to speak to a member of our technical team regarding the solenoid valves above, or to create a bespoke unit for your application call us on 01234 855888 or send us an email