Press Safety Valves

Press safety valves control the constancy of the flow of compressed air whenever compressed air becomes the power supply for the operation of pneumatic units.

In order to carry out a safety function (complying with existing norms) the valves consist of a so-called redundant system, a special surveillance circuit that stops the valve in case of air leakage in the net.

The valve inhibits the operation of the electronic panel until the failure has been fixed and the pneumatic supply restored.

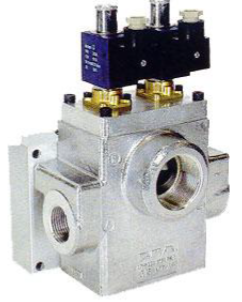

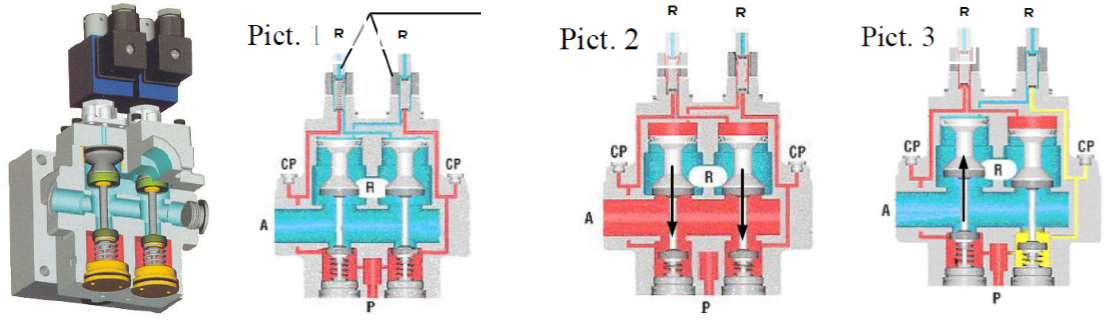

Construction Diagram Of The System

Solenoid Valve Application

View our full range of Solenoid Valves

Two 3-way solenoid valves are used in this application. When they are de-energized (Picture 1), they close the inlet of pressurized air from P (red) and connect outlet A to the exhausts R.

The value of pressure inside the pipes is controlled by pressure gauges CP. The two solenoid valves are operated at the same time by an electronic panel (Picture 2).

They close their own exhausts allowing air to flow through the pipes to the piston chambers, which are pushed downwards by pressure.

At this time air can flow from P to A.

If a failure was simulated, for example by de-energizing only the valve on the right, the piston on the left would be pushed upwards by the spring because of a lack of pressure and would open the exhaust.

Air (yellow) from P would flow towards R thus blocking the valve, which would operate again only when the system was safe. The valve would reset automatically when the stand-by position was restored.

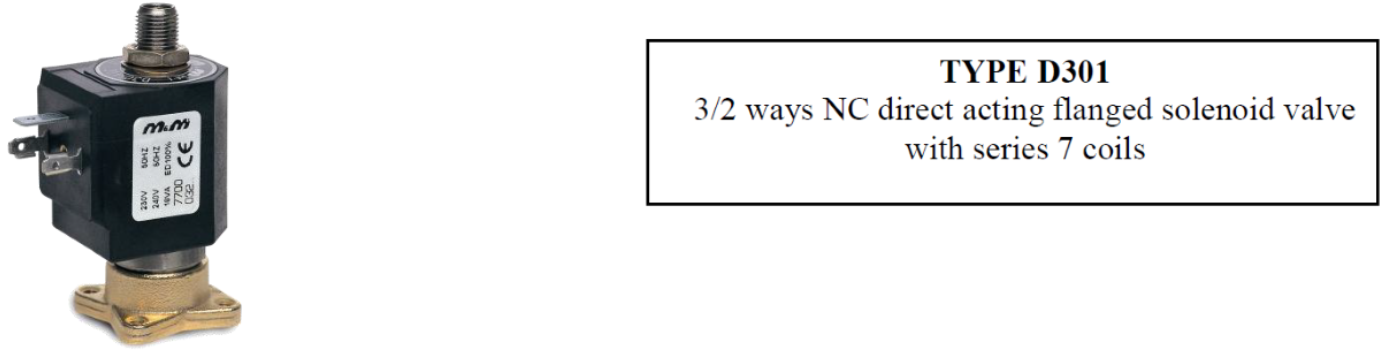

Solenoid Valves Used

You can buy M&M International Solenoid Valves online through the V-Flow Solutions web shop

This application is extremely delicate.

Since the solenoid valve performs a safety function for other units, robust and very reliable 3-way valves are needed.

If you would like to speak to a member of our technical team regarding the solenoid valves above, or to create a bespoke unit for your application call us on 01234 855888 or send us an email